Windtunnel Design & Construction – part 3: getting the parts

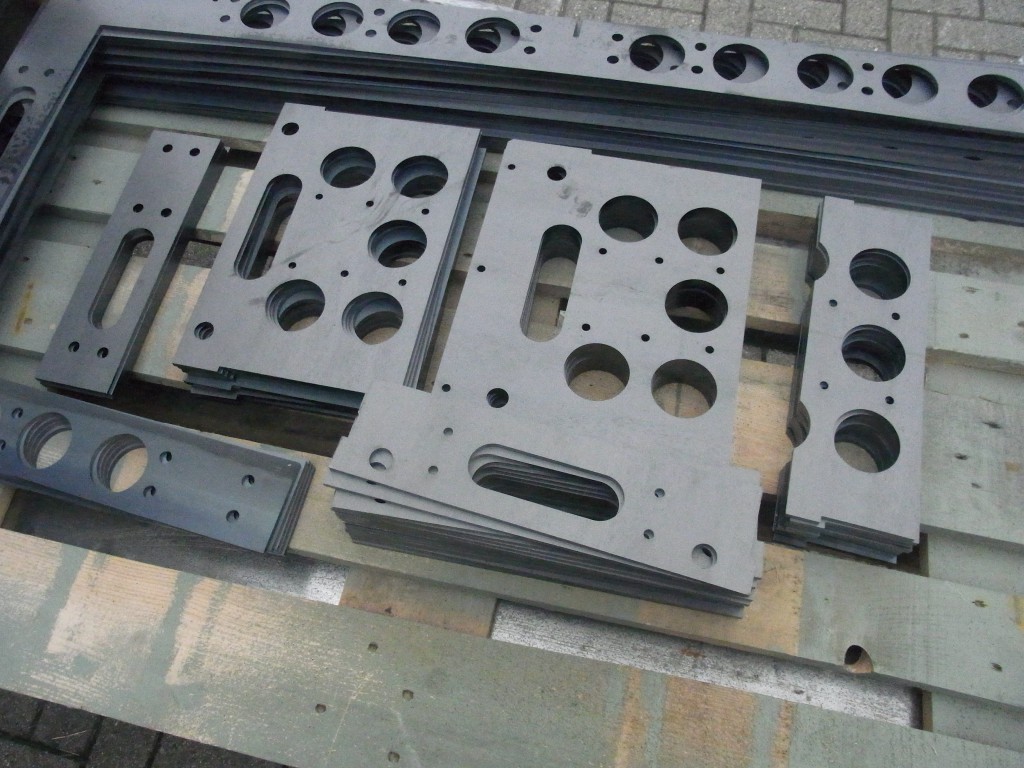

The steel parts were lasercut in serveral batches at Vandenbossche Metaalwerken, Mechelen and Provan, Genk.

The axial fan was sourced from Rucon, a distributor of Ferrari EF fans.

The type is an EF630, running at 3000RPM, with an 11kW motor.

The honeycomb is a 5cm thick aluminium honeycomb with 1/4-inch cells. It was obtained from HEXCELL.

The frequency controller for the fan is a Delta VFD – E series, bought from DamenCNC.

Castor wheels and assorted metal hardware were sourced from Misumi. and RS-components.

The paint system is a two-component polyurethane-based paint. It was sourced from deverffabriek.be.