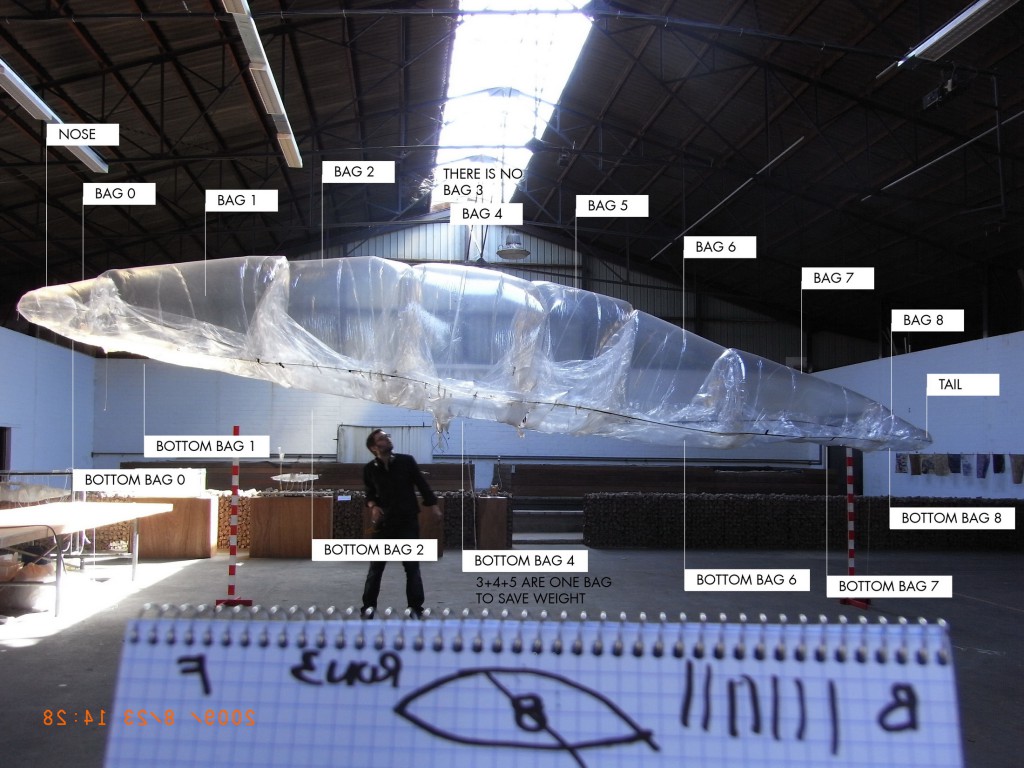

9-meter model: construction

To obtain an easier-to-build airship, the design has a flat underbelly. This shape has clear and pragmatic advantages in construction, but needs to be verified as an aerodynamic concept.

To this goal an experimental, remote-controlled model was realized in the Verbeke Foundation. Construction materials are Mylar foil, carbon fiber and Dyneema wire. Overall mass is 6,6 kg for a length of 8,6 meters. It is filled with helium.

Developing this model in a public space inside an arts center has had several advantages.

It allowed for the presentation of the project as a work-in-progress.

Showing the experiments, instead of the final results, facilitates discussion about research as a progressive series of experiments and tests through trial and error. The essence of science and engineering cannot be found in the end result, it is in the process.

This is a story that is seldom told, as our engineers are trained to work behind closed doors and only present successful results.

As a consequence, the model is not presented as a glossy, finished object. Epoxy repairs, tied-on extra parts and the Scotch tape on the gas bags show the modifications that were made during testing & development.

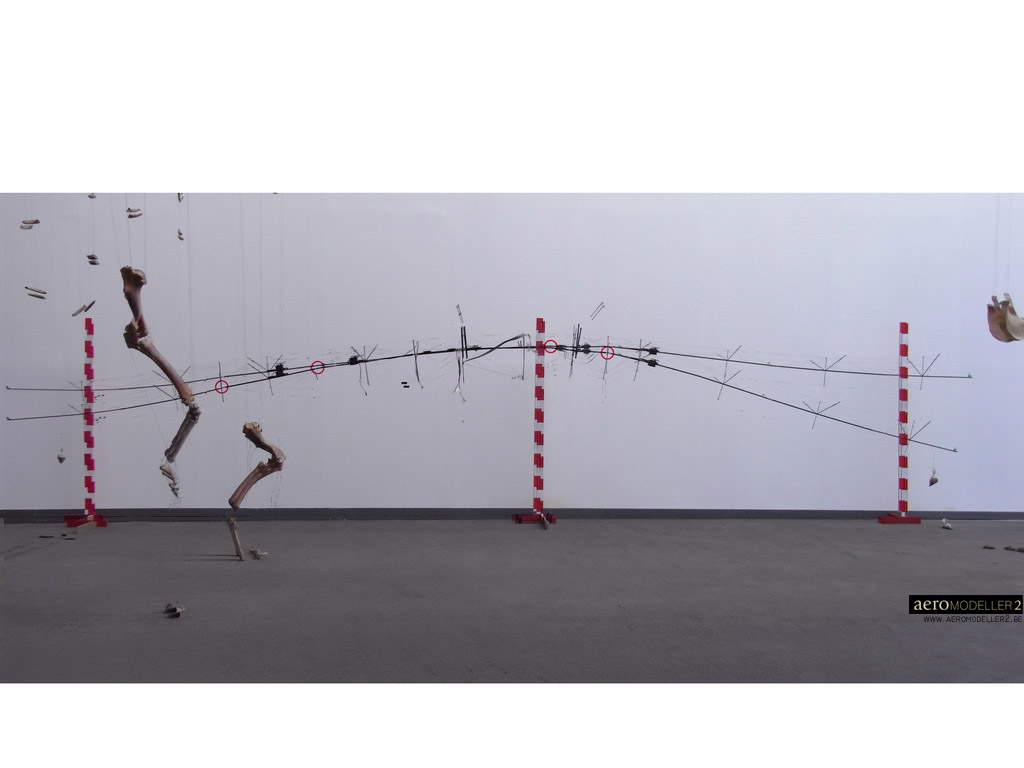

The model has an animatronic spine. Actuators control two vertical and three horizontal hinges. Bending this spine distorts the outer envelope. The gasbags slide over each other.

These deformations can be used to control aerodynamic lift and allows the ship to steer along its yaw axis.

The model has an animatronic spine. Actuators control two vertical and three horizontal hinges. Bending this spine distorts the outer envelope. The gasbags slide over each other.

These deformations can be used to control aerodynamic lift and allows the ship to steer along its yaw axis.

The model was further developed into a remote-controlled, flying model.

A conventional RC steers the device, sending signals to 2 onboard Arduinos. Xbee radios providing a telemetry link.